CAD DATA

2017-04-07SILICONE MOLDING

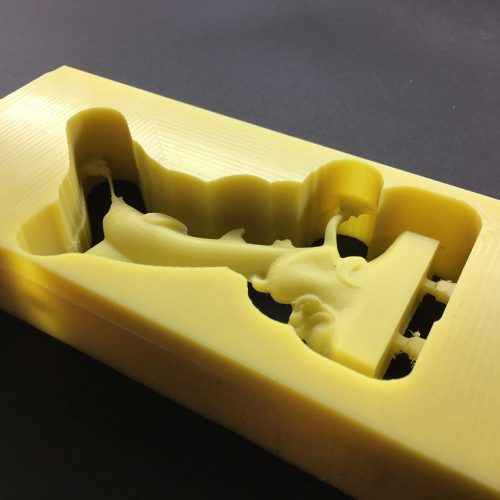

2017-04-07RAPID PROTOTYPING

Inquiry NowAt VOK, we believe in providing an integrated range of product development solutions to help designers, engineers, and manufacturers to develop and evaluate new products quickly, economically and with less risk. VOK’s success in delivering excellence over the years has been its rapid prototyping service. Using proven rapid prototype technologies, we can take your concept or design and bring it to life in just days. You will receive professional advice about the service that best suits your needs, whether that’s a prototype to test form, fit and function, or as a starting point for any of our rest manufacturing services.

In addition to form, fit, and function testing, rapid prototyping is also a great way to test different materials, finishes, and textures on your product quickly before accelerating it to market. Prototypes can also be used as masters for silicone mold, presentation models, or even functional end-use parts. These parts can also be made using final production materials which can be used in real-life environments, offering excellent opportunities for engineering evaluations.

With more than 10 years experience in rapid prototyping

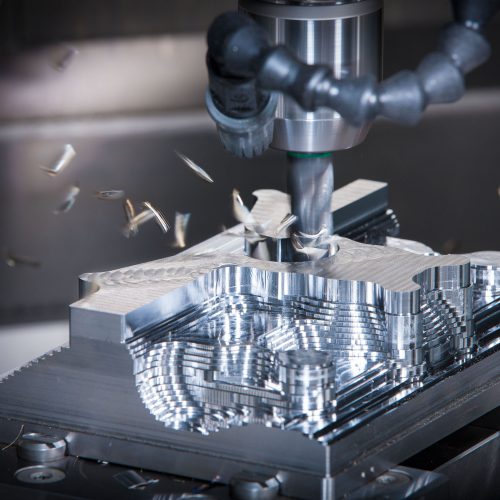

CNC milling(metal and plastic), metal machining(lathe, tapping),sheet metal processing, silicone mold vacuum casting, 3D printing and even fast steel mold are all our services for rapid prototyping.

VOK started his rapid prototyping industry since 2006. We have all kinds of material and machines to bring your products to life within a few days, sometimes overnight. At VOK, we keep our ear close to the ground for the latest developments in materials, and our experts have selected a wide range to cover most prototype applications. Our team has amassed a wealth of knowledge and experience, and will coordinate your project at every stage from the initial cost analysis to final delivery.

Sheet metal processing

Sheet metal rapid prototyping and rapid rapid production services include a variety of tooled and manual manufacturing techniques and processes. We encompass bending, shearing, staking, laser, stamping and wire cutting, as well as CNC punching, CNC folding, drilling, tapping, countersinking and counter boring. Commonly used material like cold-rolled plate, hot rolled plate, galvanized sheet, brass, beryllium, copper, aluminum, stainless steel.

CNC machining aluminum alloy

Aluminum alloy by its unique physical and chemical properties are widely used in various fields. With the process of CNC machining, lathe, stamping, tapping, press nut and surface treatment polish, sandblast, anodizing, drawbench and plating, you will get your desired product. No matter what it is function prototype or appearance prototype. Compared with other metals, aluminum alloy processing more easily, so it is very cheaper.

Reviews

There are no reviews yet.